Two-storey log house Vaher has classic beautiful design and great functional planning.

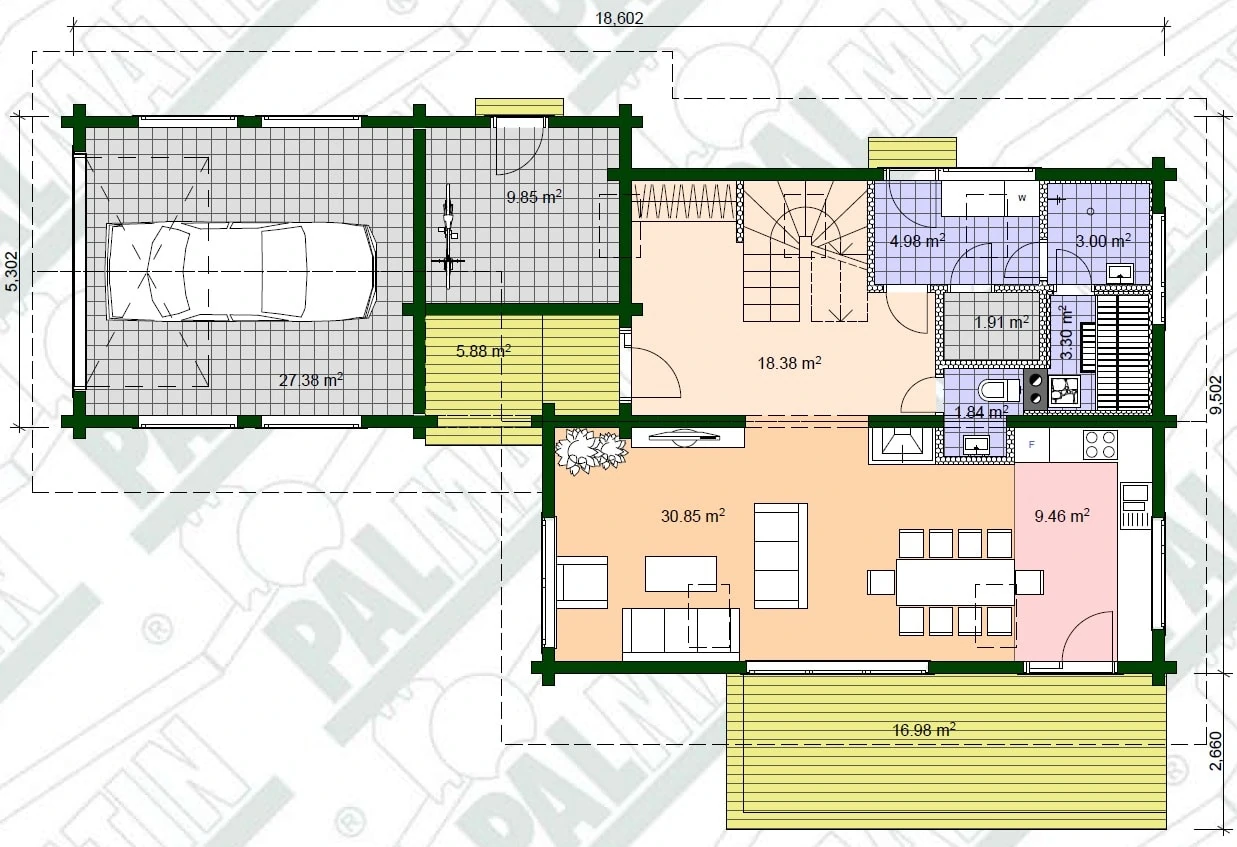

There is a garage for one car and a separate storage room for bicycles etc. Entering the house there is a nice vestibule with a staircase and next to it a large closet which can be built to a walk-in wardrobe. From the hall you can access the utilities room which leads to the bathroom and sauna. On the ground floor there is a spacious living and dining area ideal for spending time with your family or friends. The dining area is also connected to an open kitchen from where you can access the terrace.

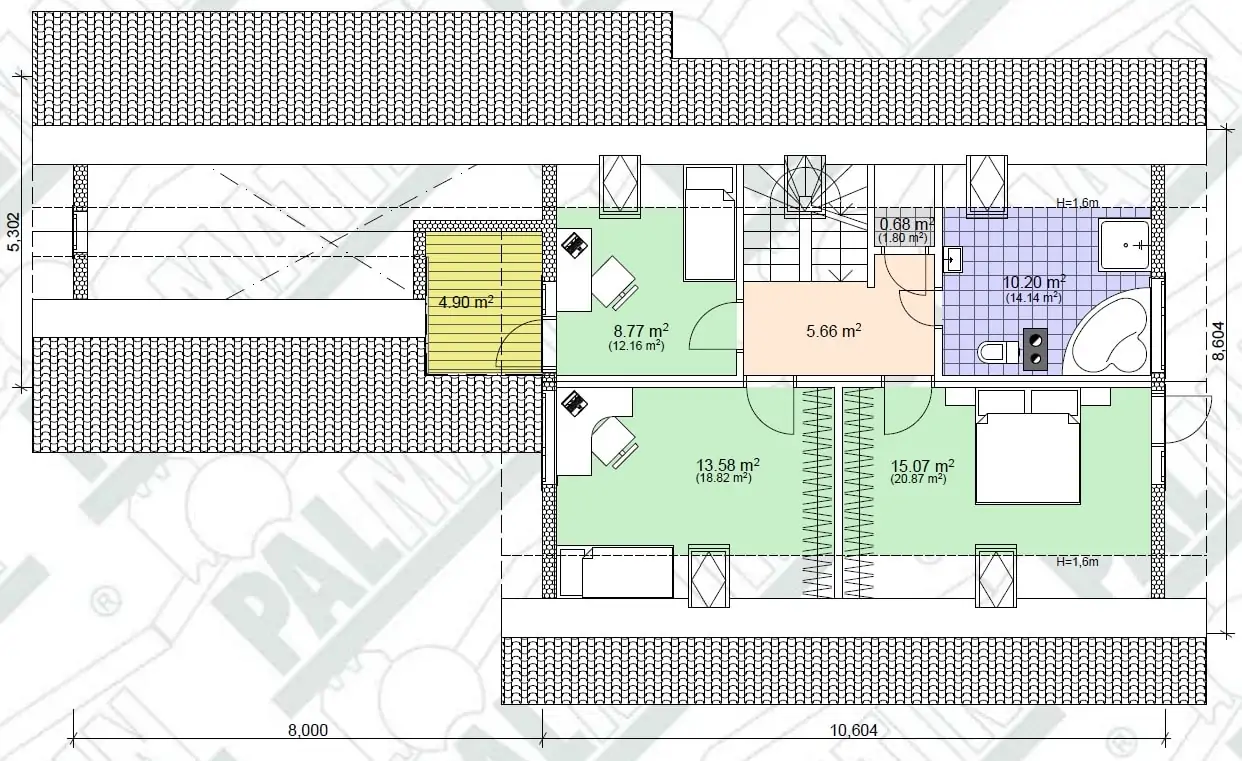

On the first floor there are 3 bedrooms, one with a balcony. There is also a small extra storage room and a second bathroom.

Get an instant quote for full price info and details below.

Instant, 3-second price quote!

"*" indicates required fields

PALMATIN CUSTOMER STORY

We selected Palmatin thanks to fast feedback and informational webpage. There were a lot of house plans and projects. Many other log house companies didn’t offer drawings. We asked price offers from 7 to 8 companies and only received two price offers – one was from Palmatin.

It is possible to use different stone materials as wall coverings. It is possible to choose from brick, decorative stone, etc. If you use stone as your external wall covering, a special cement board is installed on the prefabricated wall and the stone material will be installed thereupon on the site. In the case of stone covering, a wider foundation must be built to support the wall covering.

It is similar to a stone facade, a special cement board will be installed on the prefabricated walls. The rendering of the facade will take place on the site.

With wooden facade you have many additional options. You may choose between different cladding profiles, types of wood and the manners of treatment of the wood (varnished, painted, impregnated, etc.) Treated wooden cladding will be installed on the prefabricated walls at the factory.

The Basic Package includes all the essential materials needed to start building your log house. This package provides the production-approved drawings, load-bearing log walls, roof structures with underlay material, waterproofing, and ventilation strips. For multi-storey log houses, it also includes the structures for the intermediate floors. With this package, you receive the core construction elements necessary to assemble the main structure of your home. The Basic Package is ideal if you wish to take part in the construction process and carry out a larger portion of the work yourself while maintaining full control over the project.

The Standard Package includes everything from the Basic Package, plus all the materials needed to complete the exterior of your log house. This includes exterior finishing elements such as cladding details, mouldings, skirting boards, terraces, balconies, and wind protection materials. Windows and doors can be ordered separately and added to the package. The Standard Package is a great choice if you want your home’s exterior to be finished quickly and weather-protected, while continuing the interior works at your own pace.

The Premium Package includes everything from the Basic and Standard Packages, plus all the materials required for building the interior walls and ceilings up to the installation of building boards. All boards and fastening accessories are carefully prepared and packed for your convenience. As with the Standard Package, windows and doors can be ordered separately and included in your package. You can also add stairs, stair railings (for multi-storey houses), and roofing materials for a more complete solution. The Premium Package is the most comprehensive and convenient option, providing nearly all the materials needed to finish the log house structure and prepare it for interior completion efficiently and effortlessly.

Do you have questions about the house or would like to consult about your next project? We'd be happy to answer all your questions!

Jaan Köönvere

+372 605 48 95

Wood is a natural sound and thermal insulation, that maintains the dwelling’s climate. Thus, the house is fresh during hot summer days and warm from autumn to spring. The insulating features of the wood also minimize the energy consumption and reduce energy costs. Palmatin also proposes different insulation thickness to reinforce the natural wood insulating performances.

We use pine, but can also use spruce if a client so desires. More information under Technology

All our house models are thought out to be energy-efficient, comfortable, spacious, functional, and affordable. We are designing houses for any kind of families and suiting various locations and environments. However, we also understand that a home has to be unique and correspond to its owners, this is why it is possible to customized all Palmatin models. Very often, the final house doesn’t have much left from the model, but a house model is a good start as a base, as an inspiration and to understand the needs. You can pick a house model and discuss your needs and the transformations you would like to bring in order to create a perfect and unique house.

One of our objectives at Palmatin is to provide our clients with quality and affordable products, as the price of the houses should not control the quality of the products. To do so, we select and purchase the raw materials. We establish contact with our clients and work with them on their projects. We also monitor all stages of the manufacturing process. We assist our clients until the house assembly is completed. This process management allows us to manage our costs. Direct purchase and sales, without intermediaries, and efficient controlled production is one of the keys to a good price-quality ratio.